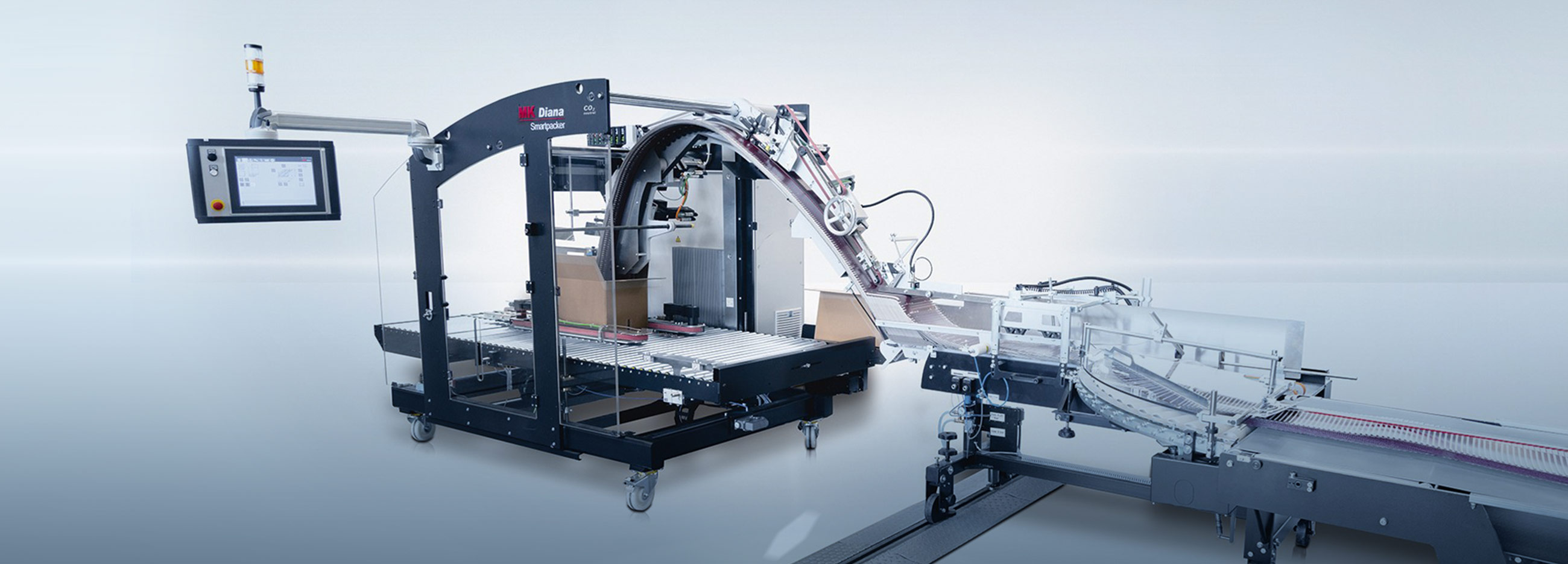

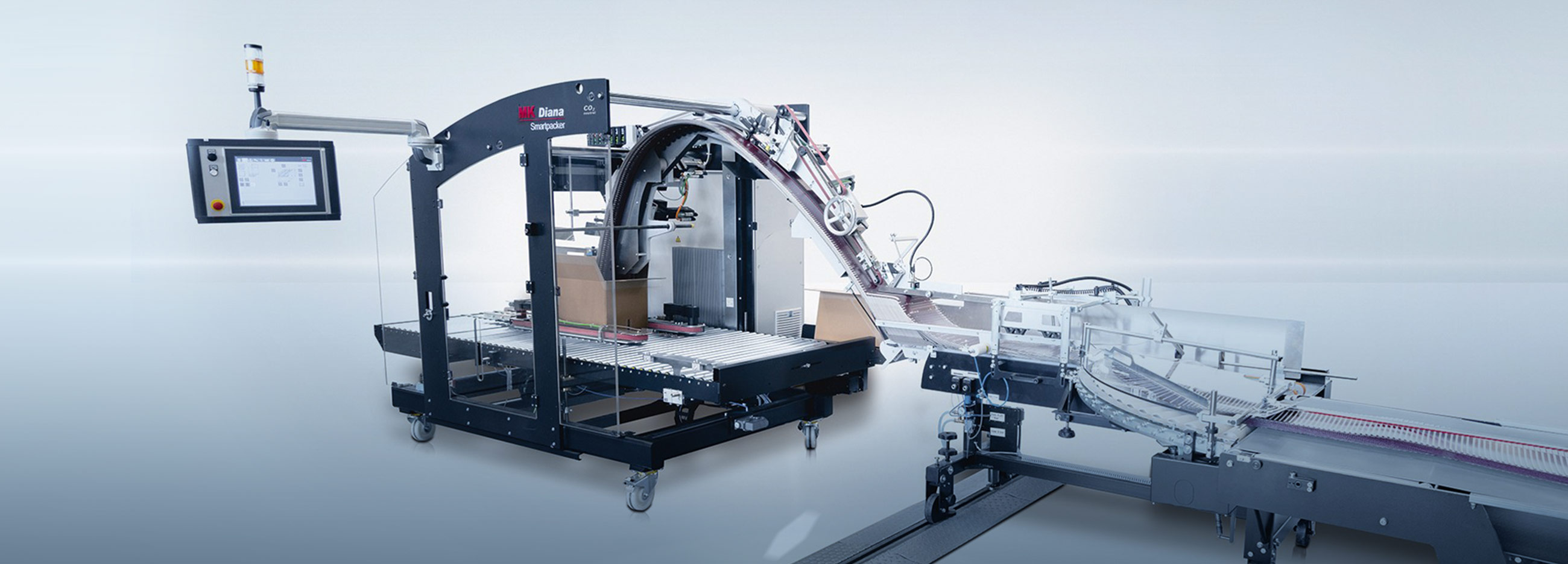

MK Packing TableDiana EasypackerDiana SmartpackerDiana Packer 4.0

The MK Diana Smartpacker packs your folding cartons fully automatically into shipping cases in one to four rows downstream of the folder gluer's compression and delivery station. An operator can also feed new shipping cases at a central control station and put sheets into the empty shipping case or insert intermediate sheets. Thus, up to three additional layers can be added semi-automatically.

The MK Diana Smartpacker can pack up to 130,000 cartons per hour in shipping cases. It is operated via a touchscreen display. The settings are calculated automatically after entering the production parameters. In addition to placing the folding cartons onto the closure flap in the shipping case, the right and left turning stations allow the cartons to be placed onto crease lines 2 or 4.

We offer labelers, sealers and palletizing robots for handling the shipping cases downstream of the Diana Smartpacker.

Interested? Contact us.

Data sheet

| Packing up to 130,000 cartons per hour | |

| High flexibility: 1 to 4 rows and 1 to 4 layers of cartons per shipping case | |

| Placement onto closure flap or crease lines 2 or 4 possible | |

| Easy handling: no need for complicated fitting of lid clamps or weights for shipping cases | |

| Short make-ready times | |

| Laser system ensures reliable counting |

As a research and development location of folder gluers and peripheral machines, we have a large test center with our own folder gluers and robots.

Our focus in Germany

Mail us: info@mkmasterwork.com

Call us: (+49)-2131-40395-0